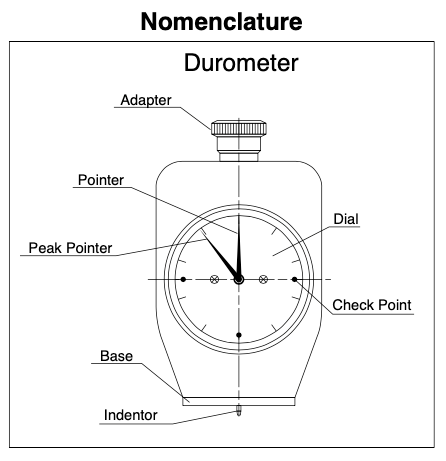

Maintenance & Precautions on use of Durometer (Rubber/Plastic Hardness measurement)

1.Confirmation of performance

Please confirm requested standard and type of durometer on the occasion of receiving. Please refer to the standard of JIS K 6253, K 7215, K 6301, ISO 7619, ISO 868 and ASTM D 2240 in detail.

2. Test environment

(1) Test environment for measuring samples is prescribed at internal and external standard as “23 ±2°C, humidity 50 ±5%”.

(2) please avoid using it where dust and oil mist attach to it.

3. Measuring Loads

Keep the measuring posture vertical and the pressing load constantas much as possible. The basic timing to read is at the time of gettingthe maximum value, but the reading after a certain past time isanother method. The timing of measurement is sometime very important and should be handled very carefully specially with a material on which the reading value starts decreasing just after pressing.

Not with a manual loading measurement, but with a measurementwith some support instrument that can generate a constant load to eliminate the dispersion caused by the difference of operator’s skill, the pressure force to the durometer will vary according to the type of durometer as follows concretely:

- Type A, E, B, O, old A = 10N (approx. 1000gf)

- Type D, C, DO, old C = 50N (approx. 5000gf)

- Type E2 = 5N (approx. 500gf)

- Type 00 = 4N (approx. 400gf)

- Type FO = Self weight measurement

These are the values of force applied to the durometer to obtain a firm contact of the Presser Foot with the specimen according to the spring load each type has.

TECLOCK supplies the CONSTANT LOADER e.g. “TECLOCK GX -610”, a product to supply the durometer with 10 N or 50 N by optional weights.

4. Precaution on use

(1) Check before using

- Confirm whether operation is smooth.

- Confirm whether accretion is on pressurized surface or indenter.

- Confirm whether the indicator indicates “0 point”.

(2) Never disassemble device and loose screws.

(3) Do not give the products any shock by being dropped or excessive load.

(4) Keep the products away from direct sun light, excessive high or low temperature, and high humidity or dust. Avoid using and storing the products under the circumstances of water or oil.

(5) Do not press the products to hard samples like glass or metals excepting for the purpose of checkup and inspection.

(6) Do not clean with organic detergent (thinner or benzine) and not put oil onto the products.

(7) Do not apply a load to the indenter in right angle. Do not hit the products with a hard item.

5. Maintenance

(1) In case that outer dial cannot be read due to dirt of crystal, please wipe stains from the crystal by using a dry cloth or a cloth dampened with neutral detergent.

(2) In case that some sort of defect is observed for indicator, indenter and spring load value by check up and repair or adjustment is needed, please inform the sales outlet where the products are bought.

6. Periodical inspection

Durometers are needed to be inspected during a certain period, which depends on usage frequency. Especially, in case that instruments are controlled by “inspection, measuring and test instruments” of ISO 9000 series, it is important element.

(1) Indenter height: Indicator should indicate 0 on free condition. Then it is checked whether indicator is in 100 by pressing pressurized surface onto hard and flat and smooth surface. Meanwhile, be careful so that indenter edge shape of Type D durometer is not changed.

(2) Indenter shape: It is checked by measuring microscope whether dimension and shape of indenter edge is in the permissible value of standard. In case that there is abrasion or damage , indenter needed to be changed.

(3) Spring force: It is checked by giving load against each indicated value whether indicator correctly indicates. Please use durometer tester like Teclock “GS-607 series” to check load of mark check point of 25, 50 and 75 on outer dial. Permissible error of indicated value is ± 1.

Above sharing just for your reference. When you’re interested in investing a durometer hardness tester to improve your quality process, select a supplier who offer a quality service and meet your specific needs.

If you have any enquiry with hardness tester, welcome to contact us by email: enquiry@mspmetrology.com

22 Jun 2023

.png)