What is Durometer Hardness Tester?

Durometers show the degree of hardness by value whether a non-rigid material like rubber is soft or hard (hardness gauge for rubber or plastic). Recently, JIS standard and ISO standard have been drastically revised and details of hardness tester of rubber and method of measuring hardness are changed.

As an all embracing manufacturer of non-rigid material hardness tester, Teclock proposes lots of measuring methods of measuring hardness of not only rubber and plastic but many non-rigid materials and elastic materials.

Model Selection of Durometer

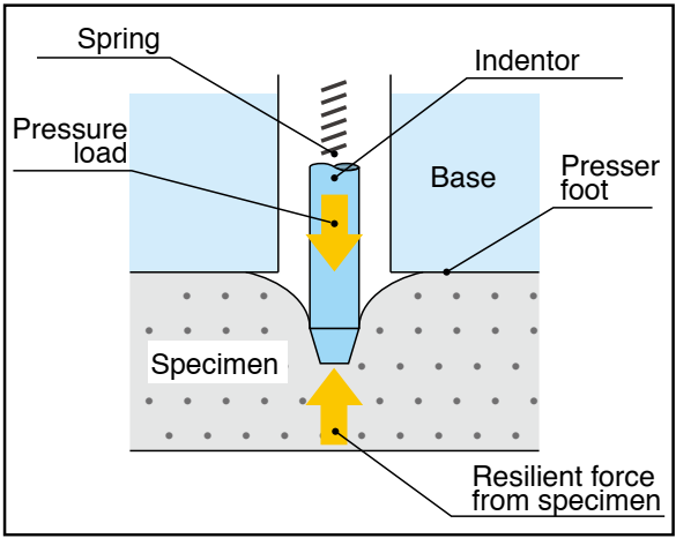

As to measured value by durometer (rubber and plastic hardness tester), when the base of durometer and work piece are cohered each other, the indenter changes shape of work piece by pressurized force caused by spring of durometer and work piece makes force against this force. Force amount of indentor is indicated as hardness when this pressurized force and repulsive force are equivalent.

If repulsive force is weak, it shows low value (soft), on the contrary, if replusive force is strong, it shows high value (hard).

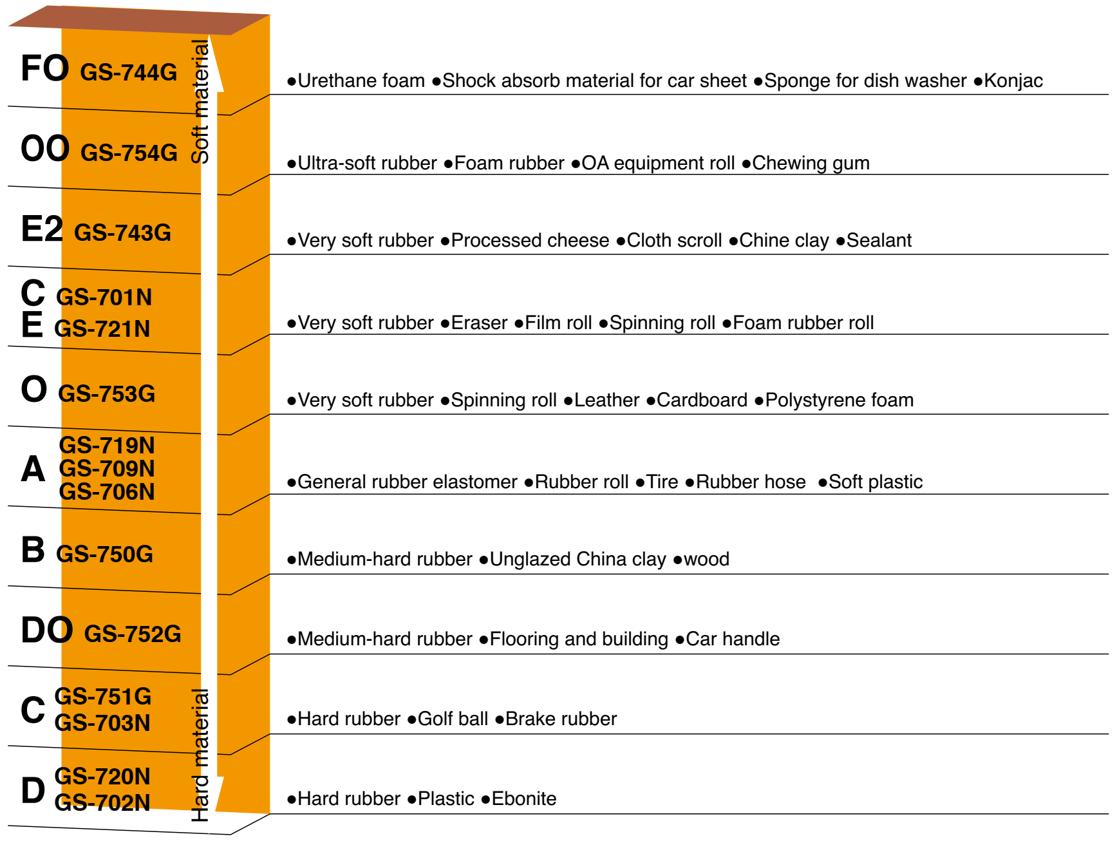

There are various type of durometers of which force of springs and shape of indentors are different. The reason why there are various kinds of durometers, it is for the purpose of showing degree of hardness with higher sensitivity against difference of material characteristics and shape of surface which work pieces have. Select a suitable product referring to the figures below:

Measuring Hardness with Durometer

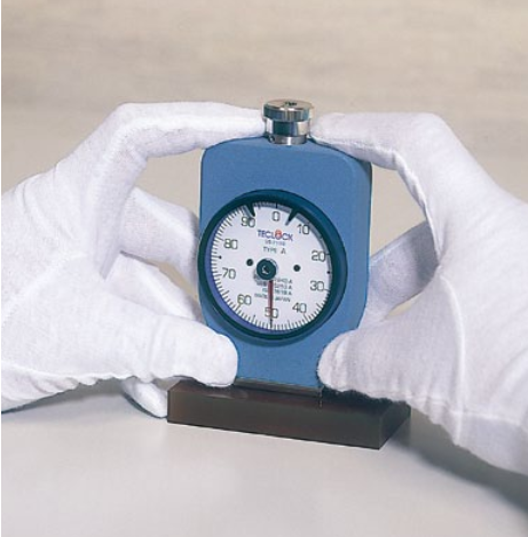

1. In case of measuring by pushing by hand, putting pressurized surface of durometer held by hand from the top vertically with a certain speed to the flat face of work piece which is put on the flat face. Then, after adhering it, regard the value measured within the passed time prescribed by standard as “hardness”.

2. In case of measuring hardness by mounting durometer to stand, measuring speed (not more than 3.2mm/sec.), pressurized load (type A, E is 1kgf, type D is 5kgf) and pressurized surface diameter (Ø18mm) of type A/D durometers including tolerance are standardized.

3. Measuring point of test piece is to be inside from its edge by 12mm or more and clearance is to be 6mm and more. Thickness is normally 6mm and more, and 10mm and more for type E.

4. Test environment: Temperature is 23°C ±2, humidity is 50 ±5% ad median or average is applied for measured value. If 50 show in type A case, it is described[A50]. These are ruled for each standard.

As to measuring hardness by pushing by hand, durometer to work piece form the top and read value by making pressed surface adhere to durometer.

In order to solve individual difference of measured value, it is clearly mentioned in the standard to measure hardness by mounting durometer to stand.

Above sharing just for your reference. When you’re interested in investing a durometer hardness tester to improve your quality process, select a supplier who offer a quality service and meet your specific needs.

If you have any enquiry with hardness tester, welcome to contact us by email: enquiry@mspmetrology.com

22 Jun 2023

.png)